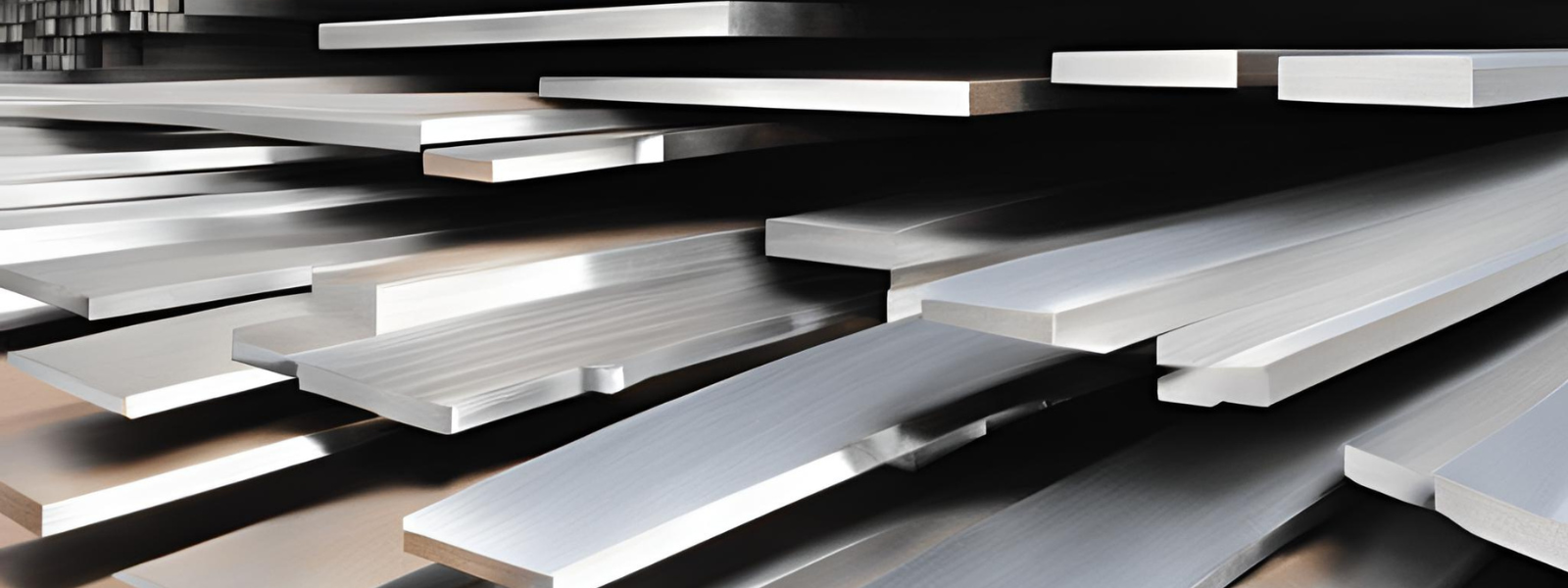

Stainless Steel Flat Bars: Versatility and Strength for Diverse Applications

Stainless steel flat bars are a staple in various industrial and architectural applications, valued for their durability, strength, and versatility. Their flat, rectangular cross-section makes them a go-to choice for structural, manufacturing, and decorative uses. This article explores the manufacturing process, applications, benefits, and different grades of stainless steel flat bars.

Manufacturing Process

The production of stainless steel flat bars involves several key stages, ensuring they meet rigorous standards for quality and performance. The process begins with melting high-quality stainless steel in electric furnaces. The molten steel is then cast into billets or slabs. These billets undergo hot rolling, where they are heated and passed through rollers to form flat bars of desired dimensions.

Once the hot rolling process is complete, the bars are subjected to cold drawing or finishing to refine their dimensions and surface quality. Cold drawing involves pulling the bars through a die to achieve precise sizes and smooth finishes. Additional treatments such as annealing or polishing may be applied to enhance the mechanical properties and appearance of the flat bars.

Applications and Benefits

Stainless steel flat bars find use in a wide range of applications across various industries due to their robust properties:

- Construction and Architecture: In construction and architectural applications, stainless steel flat bars are used for structural supports, frames, and reinforcement. Their strength and resistance to corrosion make them suitable for building components that need to withstand environmental stresses and loads.

- Manufacturing: Stainless steel flat bars are integral to manufacturing processes. They are used in the production of machinery parts, tools, and equipment. Their ability to resist wear and tear makes them ideal for high-stress environments where durability is crucial.

- Automotive Industry: In the automotive sector, stainless steel flat bars are employed in the production of components such as brackets, supports, and trim. Their resistance to rust and strength ensures that automotive parts can endure rigorous conditions and maintain structural integrity.

- Marine Industry: Due to their excellent resistance to corrosion, stainless steel flat bars are widely used in marine applications. They are used in the construction of ships, offshore platforms, and other marine structures where exposure to saltwater and harsh environments is common.

- Decorative Uses: The aesthetic appeal of stainless steel flat bars makes them a popular choice for decorative applications. They are used in the design of railings, staircases, and architectural facades, providing a sleek, modern look while ensuring durability.

Grades and Specifications

Stainless steel flat bars come in various grades, each tailored to meet specific performance criteria:

- 304: This versatile grade offers excellent corrosion resistance and is commonly used in general-purpose applications. It provides good machinability and weldability, making it suitable for a wide range of uses.

- 316: Known for its superior corrosion resistance, especially in chloride environments, grade 316 is ideal for marine and chemical processing applications. It provides enhanced protection against rust and pitting.

- 410: A martensitic stainless steel grade, 410 is known for its high strength and hardness. It is suitable for applications requiring wear resistance and can be hardened through heat treatment.

- 2205: This duplex stainless steel combines high strength with excellent corrosion resistance. It is used in demanding environments, such as in the oil and gas industry, where both mechanical strength and resistance to corrosion are essential.

Advantages of Stainless Steel Flat Bars

- Corrosion Resistance: Stainless steel flat bars are highly resistant to rust and corrosion, ensuring longevity and reducing maintenance needs in various environments.

- Strength and Durability: The flat, rectangular shape provides robust structural support, making these bars suitable for heavy-duty applications and ensuring their long-term reliability.

- Versatility: Stainless steel flat bars can be customized to precise dimensions, allowing for flexibility in manufacturing and construction projects.

- Aesthetic Appeal: The smooth, polished finish of stainless steel flat bars enhances their visual appeal, making them suitable for both functional and decorative purposes.

Conclusion

Stainless steel flat bars offer a combination of strength, durability, and aesthetic appeal, making them an essential material in various industrial, architectural, and decorative applications. Their versatile properties and rigorous manufacturing process ensure high-quality performance across a range of uses. Whether used in structural supports, manufacturing components, or decorative elements, stainless steel flat bars continue to be a preferred choice for engineers, architects, and manufacturers seeking reliable and attractive materials.